Hanford's Plutonium Finishing Plant Demolition Job Reaches Even More Delicate Phase

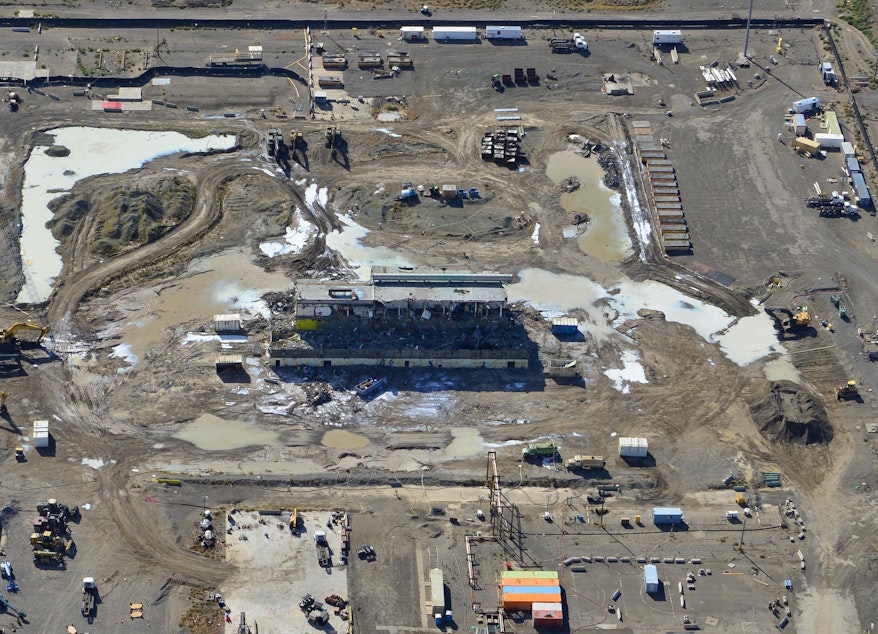

At Hanford, in southeastern Washington, contractors have just completed much of the demolition work at the site’s Plutonium Finishing Plant. But now crews have to finish the job.

And that’s the tough part.

Demo Timeline

In December 2017, demolition of the Plutonium Processing Plant — or PFP as locals call it — was in trouble. There were contaminated cars, radioactive particles found by the public highway and contamination even found on, and inside, workers.

The plant work shut down for 9 months while the contractor came up with a new safety plan.

Jason Casper is in charge of the job for CH2M Hill Plateau Remediation Company. He was brought on to straighten up the project after the contamination events. He said enhanced controls or better communication, using the suggestions from workers at the site and better use of spraying water and fixative, all have helped to keep fresh contamination events at bay.

“The most basic thing that we use to control contamination, is the application of a water mist,” Casper explained.

Sponsored

“Just like putting water on a road, water keeps the dust down. Fixative is basically paint, and applying paint to those surfaces that may have contamination keeps that contamination locked into place so we can package it appropriately.”

90% There

More than 90% of the demo is now complete. But that leaves some of the toughest, most contaminated parts of the plant to go after — including two plutonium processing lines, and underground utility tunnels full of water with pipes holding plutonium.

Casper said that on this new phase of the project, he’s mostly worried about the people he’s in charge of, and of industrial accidents.

“We have a lot of equipment that we’re running,” he said. “So making sure people stay safe in all respects. From not having issues with equipment, not having issues walking to the work area, to the radiological area and making sure it’s not being spread.”

Sponsored

The History

PFP started in 1949. It’s where the federal government turned liquids with plutonium into hockey-puck-sized solid plutonium “buttons” for nuclear weapons. It was also known as the “Z” Plant, because it was the last stop for plutonium processing before being shipped off Hanford.